Serial Real-time Communications System (SERCOS) is an international standard for high-speed motion control networking.

Transforming the World to Polymer Optical Fiber

Showing all 11 results

Serial Real-time Communications System (SERCOS) is an international standard for high-speed motion control networking.

Plastic optical fiber is able to withstand extreme ranges of operating temperatures.

When a plastic optical fiber undergoes a physical change, such as bending, the light passing through it undergoes changes that are detectable, allowing it to be used as a sensor.

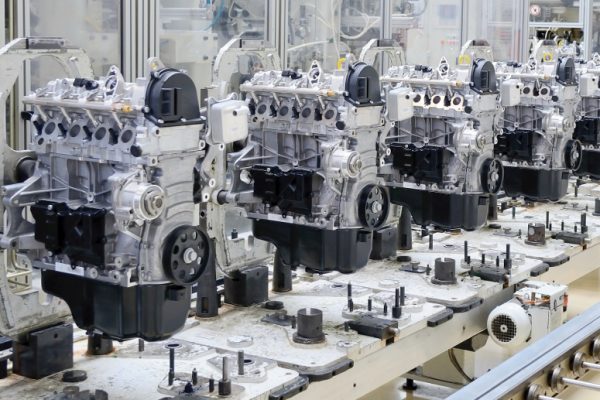

Industrial networks have taken advantage of the properties of plastic optical fiber for decades, using IEEE 1394, Ethernet/IP, and other networking standards.

Plastic optical fiber can withstand heat, direct sunlight, and, with the right components, dust and moisture.

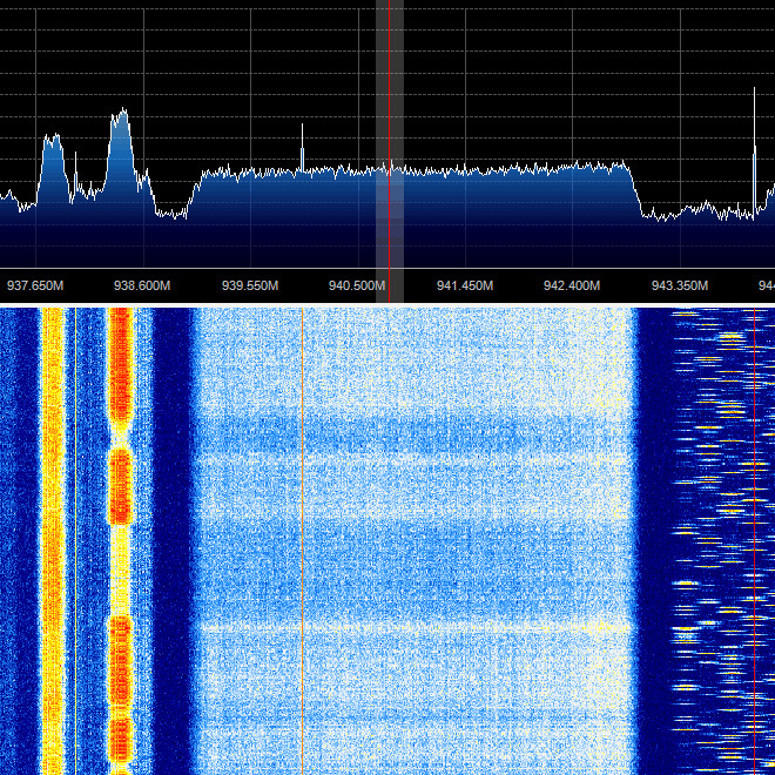

Because POF is made of insulating materials, it can provide electrically isolated data links in environments and applications where electrical isolation is critical. Image: NAVFAC / Flickr (source) (CC BY 2.0)

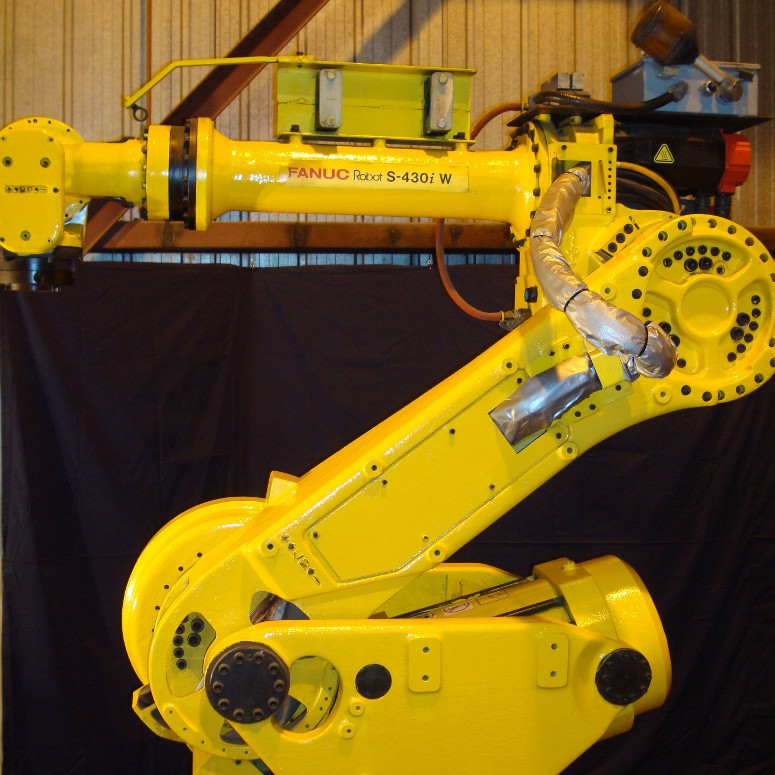

lastic optical fiber is the medium of choice for data links in manufacturing equipment. Image: Kitmodo Marketplace / Flickr (source) (CC BY 2.0)

Plastic optical fiber offers complete immunity to EMI, because it is made entirely of insulating materials.

POF brings several key advantages over copper and glass to every application that it is used in. Image: verkeorg / Flickr (source) (CC BY-SA 2.0)

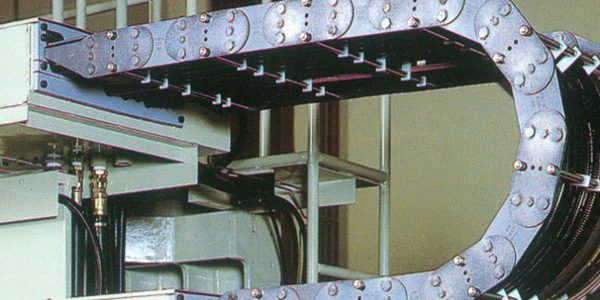

Plastic optical fiber is resilient to physical strains, making it the superior choice for industrial data.

Plastic optical fiber’s physical resiliency and immunity to interference lends itself to especially well to industrial applications, including high-speed network links, robotic motor control, and harsh operating environments.

FiberFin Proudly Sponsors No Boundaries Cornament for a Cause FiberFin was honored to sponsor and participate in the No Boundaries Cornament for a Cause held on October 8th. The event raised over $156,000 in support of combat-wounded veterans, providin …

Learn MoreFiberFin, Inc.

9925 State Route 47 Unit A

Yorkville, Illinois 60560

United States of America

Product support: info@fiberfin.com

Sales inquiries: sales@fiberfin.com