Effects of Chemicals on Plastic Optical Fiber

Plastic optical fiber is resistant to many oils and solvents found in industrial environments or manufacturing plants, making it ideal for data links and sensors that must be immersed in such chemicals. The following page outlines the effects of various chemicals on Mitsubishi ESKA® fiber optic cable.

The information contained herein is presented as a guide to product selection. It is subject to change without notice, and should not be regarded as a representation, warranty or guarantee with regard to the quality, characteristics or use of this product.

Adhesive Chemical Resistance

Since PMMA, the most common polymer used for POF cores, is damaged by chemicals with high amine contents, instant adhesives that use cyanoacrylate should not be used with POF cable and connectors.

Non solvent-type epoxy adhesives are recommended for making POF cable assemblies, but hardeners containing amines should be avoided. Since each adhesive manufacturer uses their own recipe, it is important to test the effects of the adhesives on cores and jackets before use. FiberFin uses and recommends a variety of adhesives, including:

- Glenmarc Industries GER3000 / GEH4000

- Epoxy Technology EPO-TEK 310M

- Tra-Con TRA-BOND F113SC

- Master Bond E21-7P

Fiber Chemical Resistance

The following table lists test results from submersion tests of Mitsubishi ESKA® fiber in various solvents and oils. To pass a test, a cable must not undergo any significant (greater than 1 dB) transmission loss change, or physical change (cracking, swelling, or melting, etc.). Tests were carried out for 24 hours.

| Chemical Agent | Property | ESKA® GK-40 Bare Fiber | ESKA® GH-4001 Cable |

|---|---|---|---|

| Oil ATSM #3 (50°C) | Optical Transmission | Pass | Pass |

| Visual Inspection | Pass | Swelling | |

| Brake Fluid (SAE J1703) (50°C) | Optical Transmission | Fail (after 2 hours) | Pass |

| Visual Inspection | Cracking | Swelling | |

| Transmission Oil (GM 6137M) (50°C) | Optical Transmission | Pass | Pass |

| Visual Inspection | Pass | Swelling | |

| Antifreeze (GM 1825M) (50°C) | Optical Transmission | Pass | Pass |

| Visual Inspection | Pass | Pass | |

| Gasoline (25°C) | Optical Transmission | Fail (after 2 hours) | Fail (after 4 hours) |

| Visual Inspection | Cracking | Swelling | |

| Windshield Washer Fluid (25°C) | Optical Transmission | Pass | Pass |

| Visual Inspection | Pass | Pass | |

| 5% NaCO Solution (25°C) | Optical Transmission | Pass | Pass |

| Visual Inspection | Pass | Pass | |

| Diesel (#2) (25°C) | Optical Transmission | Pass | Pass |

| Visual Inspection | Pass | Swelling | |

| Carburetor Cleaner (25°C) | Optical Transmission | Fail (after 2 hours) | Fail (after 4 hours) |

| Visual Inspection | Cracking | Swelling |

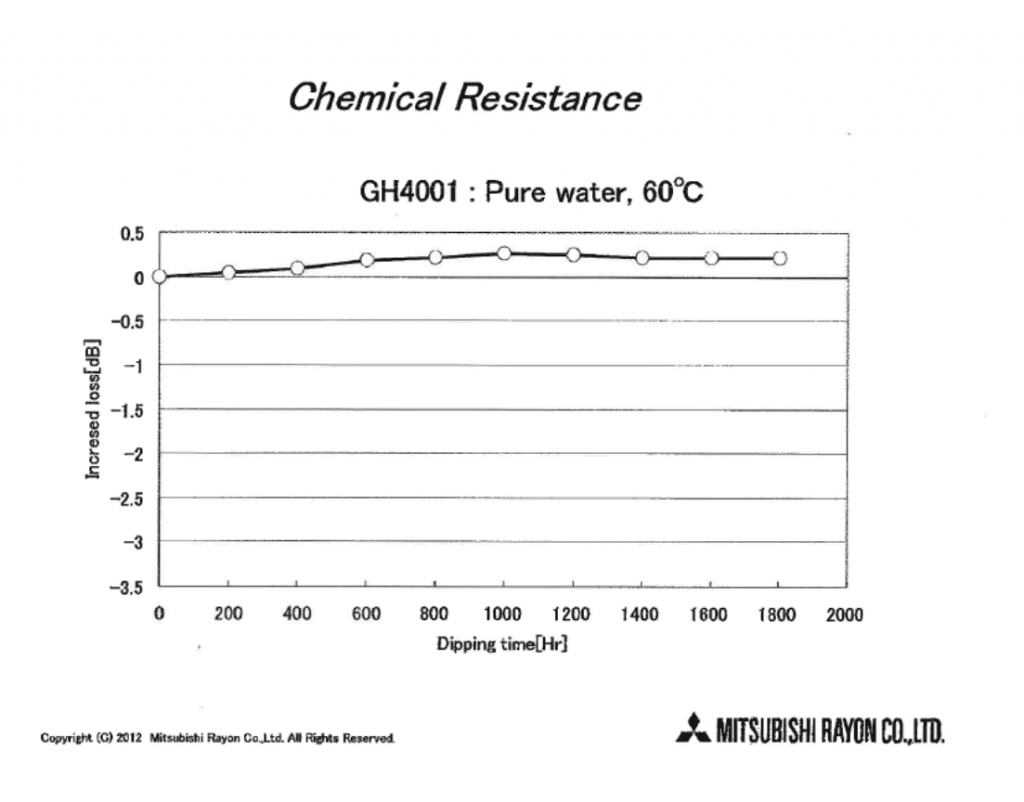

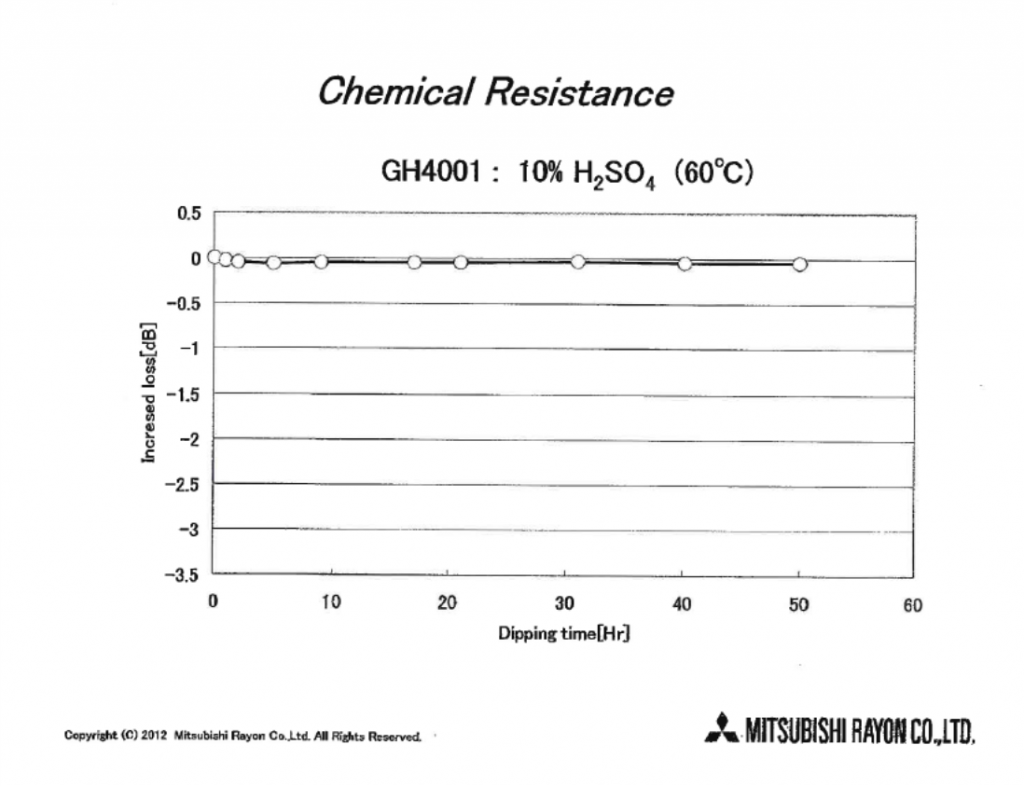

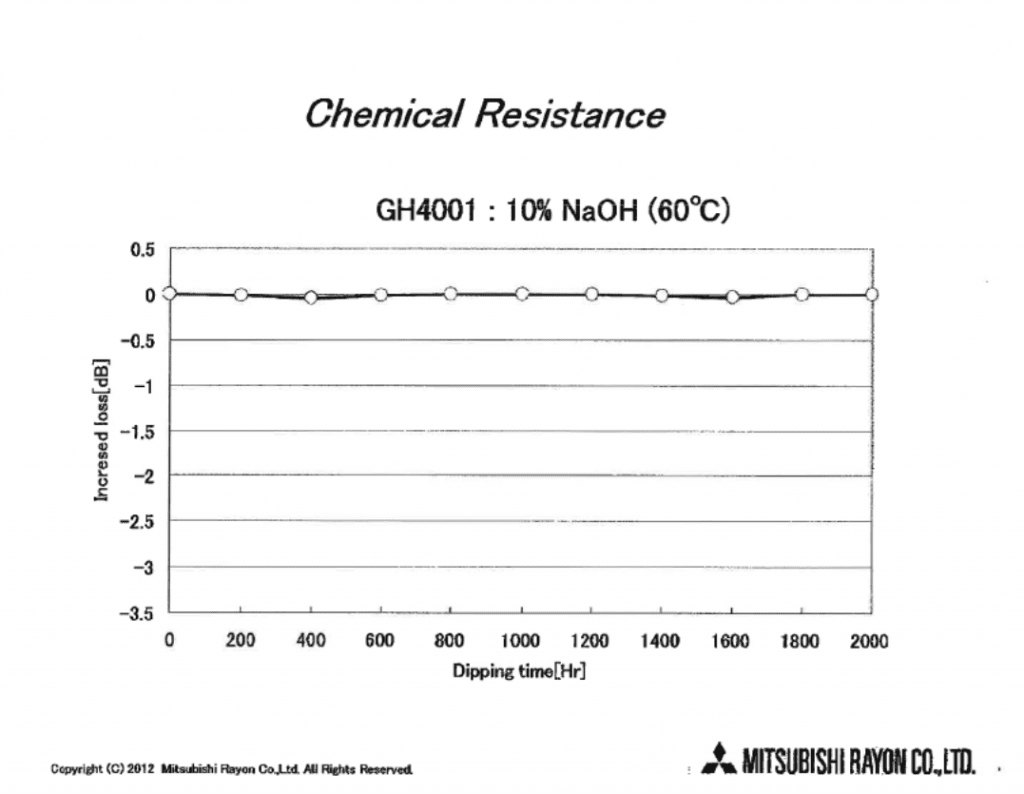

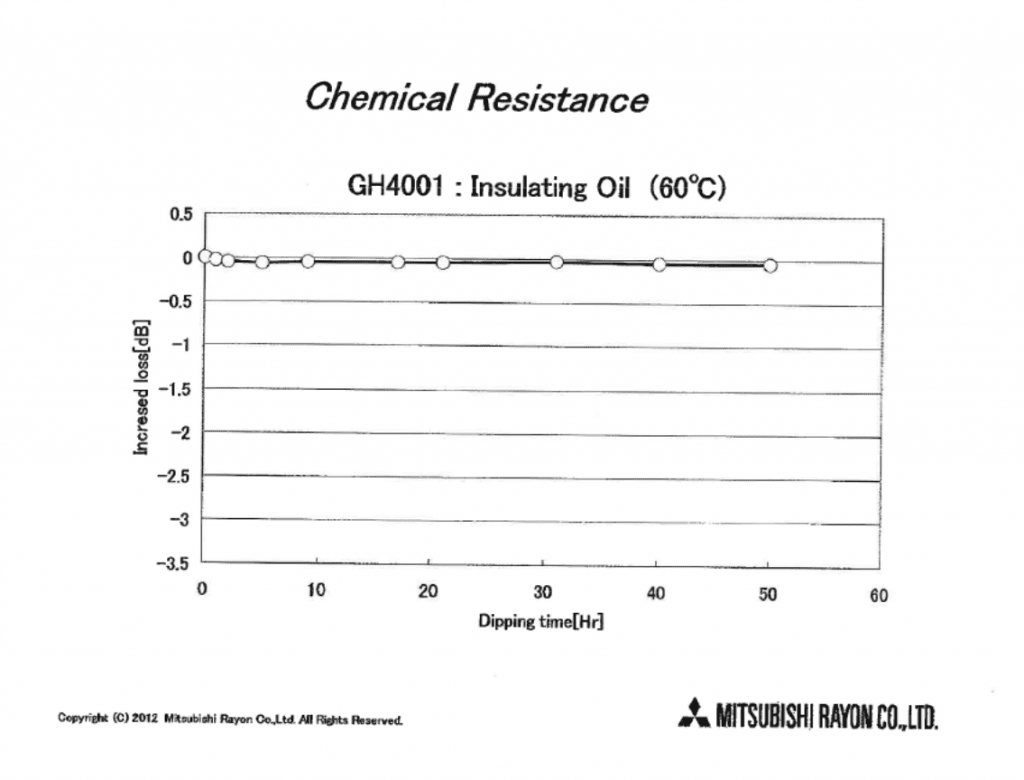

Attenuation Over Time

The following plots show the effect of various chemicals on the attenuation loss of Mitsubishi ESKA® fiber optic cable.