Mechanical Advantages of Plastic Optical Fiber

One of the key advantages of plastic optical fiber over copper wire or glass optical fiber is its physical resiliency. Fiber manufacturers quantify this through strenuous tests, carried out by machines that repeatedly bend, pull, and impact the fiber. Here, we highlight Mitsubishi ESKA plastic optical fiber, but these superior mechanical properties are applicable to all kinds of POF. All test data presented here has been provided by Mitsubishi Rayon Co., Ltd unless otherwise specified.

The information contained herein is presented as a guide to product selection. It is subject to change without notice, and should not be regarded as a representation, warranty or guarantee with regard to the quality, characteristics or use of this product.

Flex Cycle Resilience

Mitsubishi ESKA® POF cable is rated to over 5,000,000 flex cycles over its lifetime, making it ideal for use in factory automation equipment. This makes for POF cable that can easily withstand day-to-day handling, as well as industrial environments, where cables are subject to millions of flex cycles over their service life.

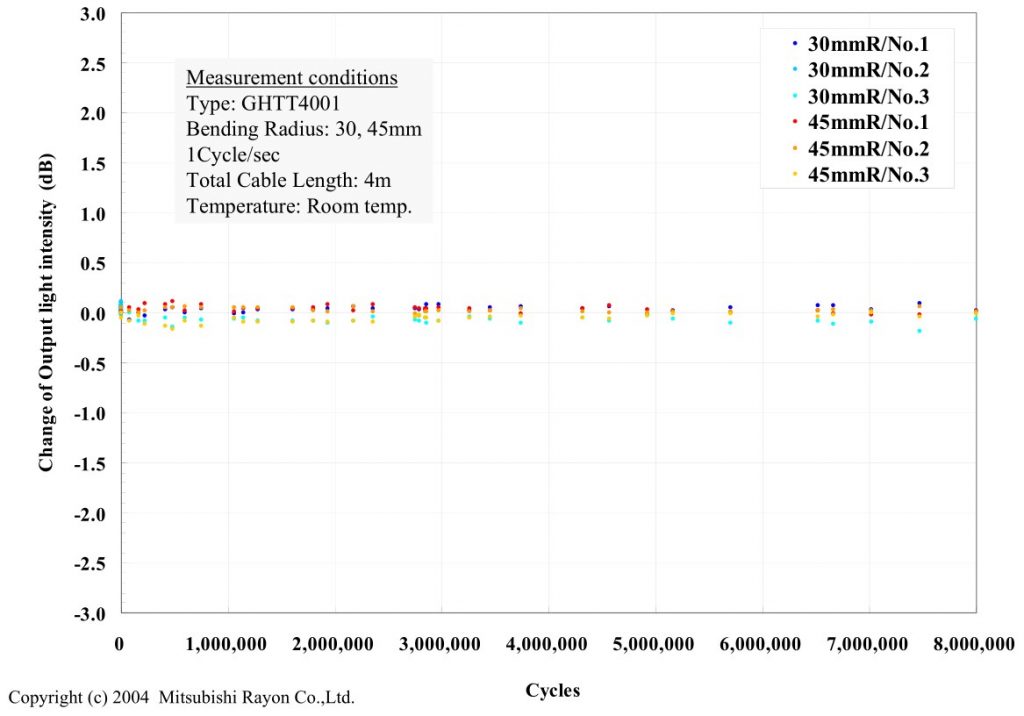

Repeated Bend Resilience

Similar to flex cycle tests, repeated bending tests quantify how many times a fiber can be bent to the same position and back before any significant signal loss occurs.

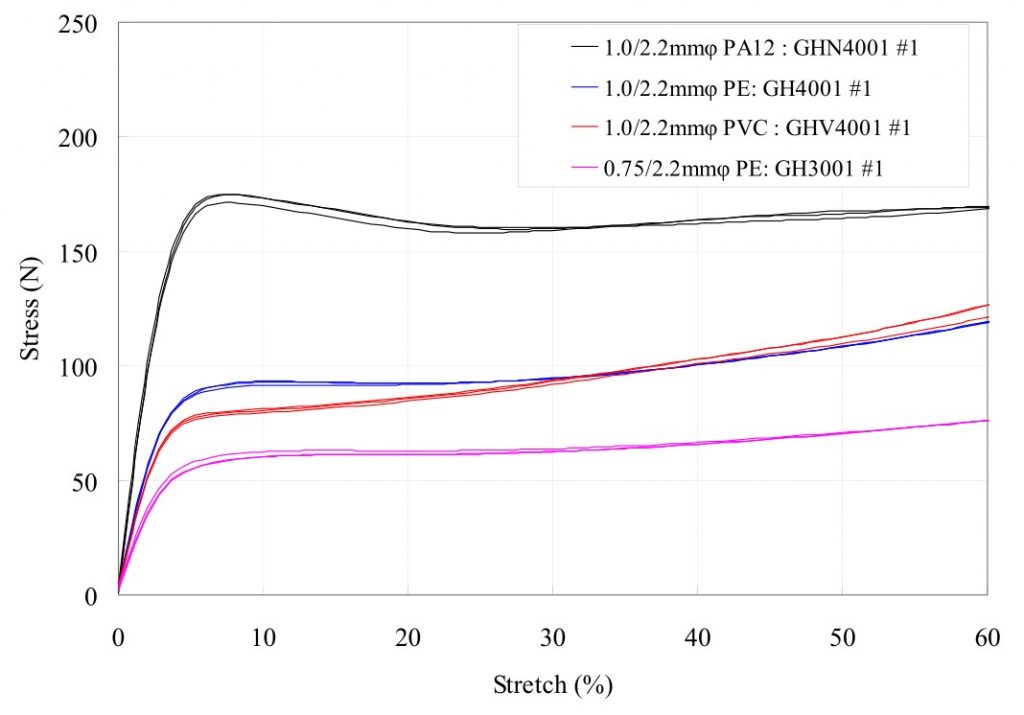

Tensile Strength

Tensile strength describes the amount that a strand of fiber stretches when subjected to a specified amount of force. In a real-world environment, this may take the form of an accidental tug or strain on a cable that is connected to a stationary device.

Impact Resistance

Impact resistance describes a fiber’s ability to withstand impacts of a specified force without deformation and consequent signal loss. This test addresses scenarios where, for example, a fiber run across a factory floor may be stepped on or run over inadvertently.