Plastic Optical Fiber in Medical Instruments

In addition to high speed communication in environments sensitive to electromagnetic interference, fiber optics are a part of many sensors that are developed and used for medical applications to monitor tissue and chemicals, and to make medical imaging image less invasive than other techniques.

Medical Applications

Medical imaging technologies such as MRI, CAT, PET, and X-ray scanners use high voltages to power coils or X-ray tubes. This generates significant electromagnetic interference (EMI) in the equipment and surrounding environment. Designers of these systems look to fiber optic cable to protect patients and equipment against the effects of this unwanted electromagnetic energy.

Read more about POF in medical scanners

In general, POF’s uses in the medical field fall into two main categories: As a probe, for imaging, analysis, and sensing, and as a power source, for treatment, therapeutics, and task/instrument lighting.

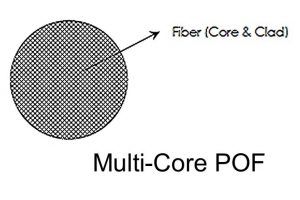

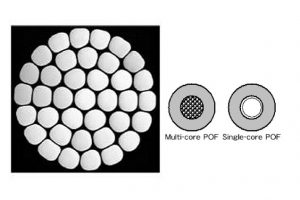

Patents exist for in vivo optical systems that can monitor tissue in live patients during operation that previously required samples to be removed. This is done through passive endoscopes that incorporate multicore fiber. A paper published by The Journal of Biophotonics in 2013, available here, describes the use of an endoscope like this to help diagnose stomach cancer.

Fiber Optic Imaging

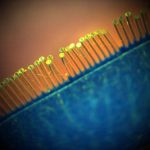

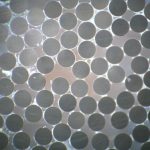

Fiber optic imaging has seen a myriad of uses across many different industries. At its core, the optical transmission properties of fiber are used to transmit a complete image from end to end. To accomplish this, an image guide or coherent bundle of fiber is used to collect an image of the target or subject area, which is then relayed to the other end.

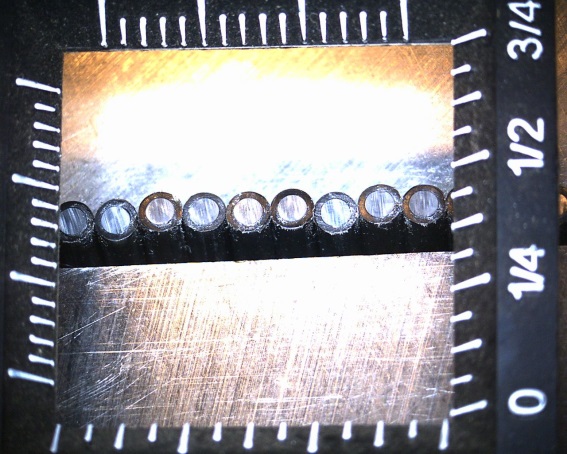

Imaging applications require individual fibers to be aligned, fused, and bundled to create an image guide. This is necessary because a single fiber optic cable is only capable of transmitting a single color of a given intensity, which is received at the light source or subject area. By bundling several, in some cases thousands, of individual fibers, an complete image can be collected and transmitted.

Fiber Optic Sensors

POF’s versatility lends it to a variety of sensor applications. In the medical field, it is often preferred over conventional sensors, since it is:

- Comprised of dielectrics, with no risk of grounding issues or electrical connections to patients

- Minimally invasive due to small size

- Immune to EM/RF interference, and does not interact with microwave/RF diathermy fields

- Inexpensive and conducive to batch fabrication

- Biocompatible and sterilizable

FDA Certified Fiber

Mitsubishi offers FDA-certified PMMA fiber cores for medical use, including surgical applications, endoscopy, and lighting. This allows for medical manufacturers to easily design in and incorporate POF into their application-driven products.

Medical Fiber Finishing

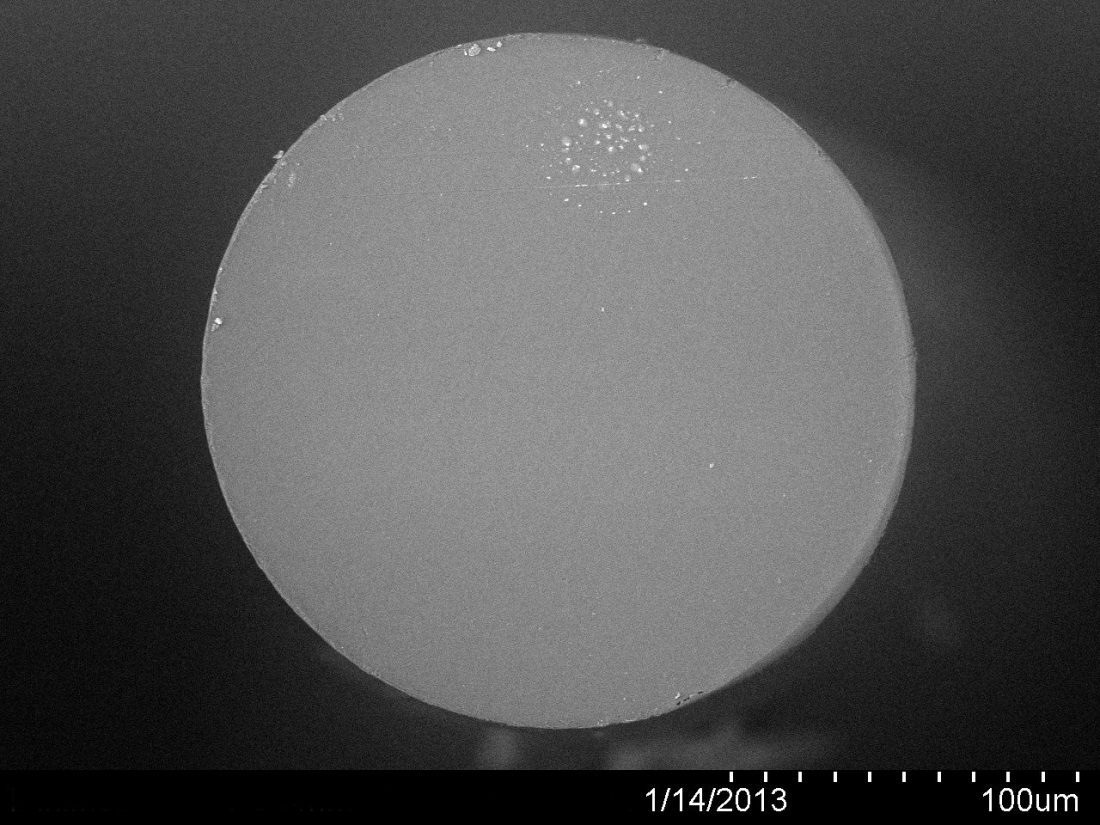

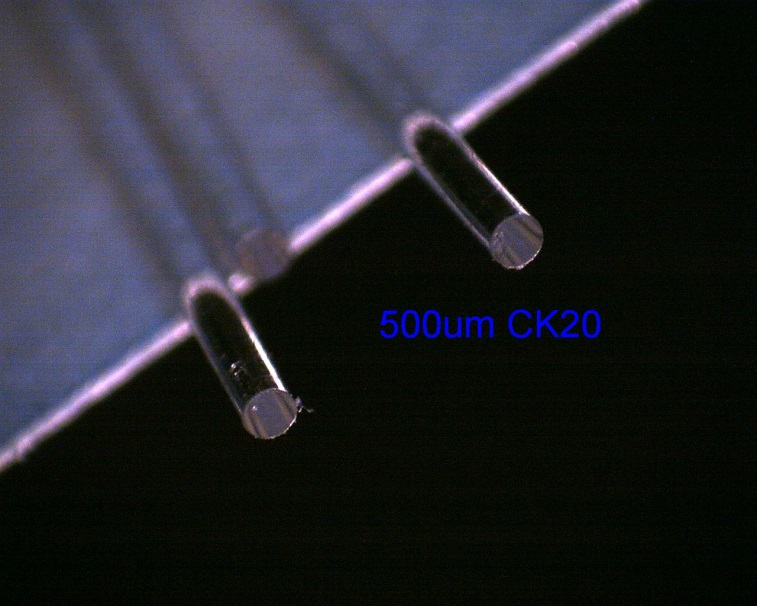

FiberFin’s proprietary finishing process lends itself to the medical field for medical optical fiber imaging and sensor applications. This process allows us to finish, or polish, POF to a mirror-like surface, down to 150μm in diameter, with a surface polish of no more than 3μm RMS.